When it comes to busbars in electrical systems, the choice of material can significantly impact performance and efficiency. Two of the most common materials used are aluminum and copper. At AP Precision Metals in San Diego, California, we frequently encounter questions about which material is better suited for various applications. In this article, we’ll delve into the differences between aluminum vs copper busbars, providing you with a comprehensive understanding of each to help you make an informed decision.

Introduction to Busbars

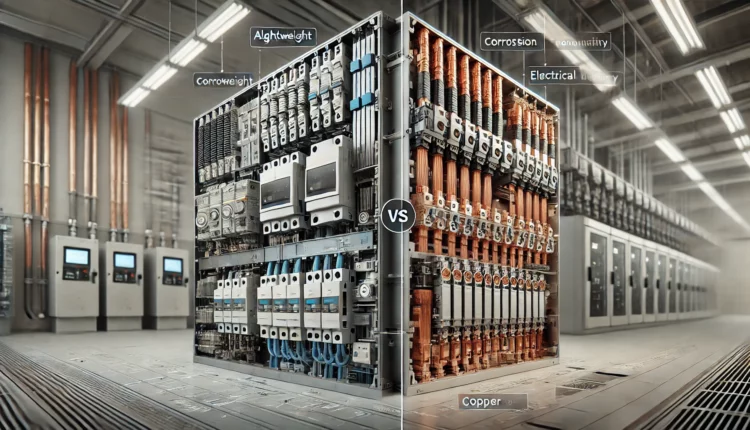

Busbars are metallic strips or bars used in electrical power distribution to conduct electricity. They are crucial components in electrical panels, switchgear, and substations. The primary materials used for busbars are aluminum and copper, each offering distinct advantages and disadvantages.

Aluminum Busbars

Aluminum busbars are widely used in electrical systems due to their numerous benefits. Here are some key characteristics of aluminum busbars:

- Lightweight: Aluminum is significantly lighter than copper, which makes it easier to handle and install. This can be especially advantageous in applications where weight is a critical factor.

- Cost-Effective: Aluminum is generally less expensive than copper, making it a cost-effective choice for many projects. The lower material cost can lead to substantial savings, especially in large-scale installations.

- Corrosion Resistance: Aluminum forms a protective oxide layer that helps resist corrosion. This makes it suitable for use in environments where corrosion is a concern.

However, aluminum has its drawbacks. It has lower electrical conductivity compared to copper, which means larger cross-sectional areas are needed to carry the same current. This can sometimes offset the cost and weight advantages.

Copper Busbars

Copper busbars are known for their excellent electrical conductivity. Here are some advantages of using copper busbars:

- High Conductivity: Copper has superior electrical conductivity, which means it can carry more current than aluminum of the same size. This makes it ideal for applications where high efficiency is required.

- Durability: Copper is a more durable material, capable of withstanding high temperatures and mechanical stress. This makes it suitable for demanding environments.

- Thermal Conductivity: Copper’s high thermal conductivity helps in better heat dissipation, reducing the risk of overheating.

Despite these benefits, copper is heavier and more expensive than aluminum, which can be a disadvantage in some applications.

Comparative Analysis

To provide a clear understanding of the differences between aluminum and copper busbars, let’s compare them based on key factors:

- Electrical Conductivity: Copper’s electrical conductivity is about 60% higher than that of aluminum. This means that for the same current-carrying capacity, a copper busbar can be smaller in size compared to an aluminum busbar.

- Weight: Aluminum is approximately one-third the weight of copper. This makes aluminum busbars easier to handle and install, particularly in applications where reducing weight is important.

- Cost: Aluminum is generally cheaper than copper, making it an attractive option for budget-conscious projects. However, the need for larger sizes to match copper’s conductivity can sometimes reduce the cost advantage.

- Corrosion Resistance: While both materials have good corrosion resistance, aluminum’s natural oxide layer provides additional protection in corrosive environments.

- Thermal Expansion: Aluminum expands and contracts more than copper with temperature changes. This can affect the integrity of connections over time if not properly managed.

Practical Applications

Aluminum busbars are often used in applications where weight and cost are critical factors, such as in large-scale power distribution systems, automotive, and aerospace industries. Their corrosion resistance also makes them suitable for outdoor applications.

Copper busbars are preferred in applications that demand high electrical efficiency and durability, such as in electrical substations, industrial settings, and critical power systems. Their superior conductivity and thermal performance make them ideal for high-current applications.

Making the Right Choice

Choosing between aluminum and copper busbars depends on the specific requirements of your application. Here are some tips to help you decide:

- Assess Your Budget: If cost is a primary concern, aluminum may be the better choice due to its lower price. However, consider the long-term costs associated with larger sizes and potential efficiency losses.

- Consider Weight: For applications where weight reduction is essential, aluminum’s lightweight nature can provide significant advantages.

- Evaluate Performance Needs: If your application requires high electrical efficiency and durability, copper’s superior conductivity and robustness may outweigh its higher cost and weight.

Conclusion

Understanding the differences between aluminum and copper busbars is crucial for making informed decisions in electrical power distribution. Each material has its unique set of advantages and disadvantages, and the best choice depends on your project’s specific needs. At AP Precision Metals, we are committed to providing high-quality busbars tailored to your requirements. Whether you choose aluminum or copper, our team of experts is here to help you achieve optimal performance and efficiency.

For more information on our products and services, feel free to contact us or visit our website. We look forward to assisting you with your next project!

When comparing aluminum vs copper busbars, it’s essential to consider factors like electrical conductivity, weight, cost, and durability. Aluminum busbars are lightweight and cost-effective, making them ideal for large-scale projects where budget and weight are critical. On the other hand, copper busbars offer superior electrical conductivity and durability, making them suitable for high-efficiency and demanding applications. By understanding the unique benefits of each material, you can make a well-informed decision that aligns with your project’s specific needs. Whether you’re looking for cost savings with aluminum or high-performance with copper, AP Precision Metals has the expertise and products to meet your requirements.

Comments are closed.