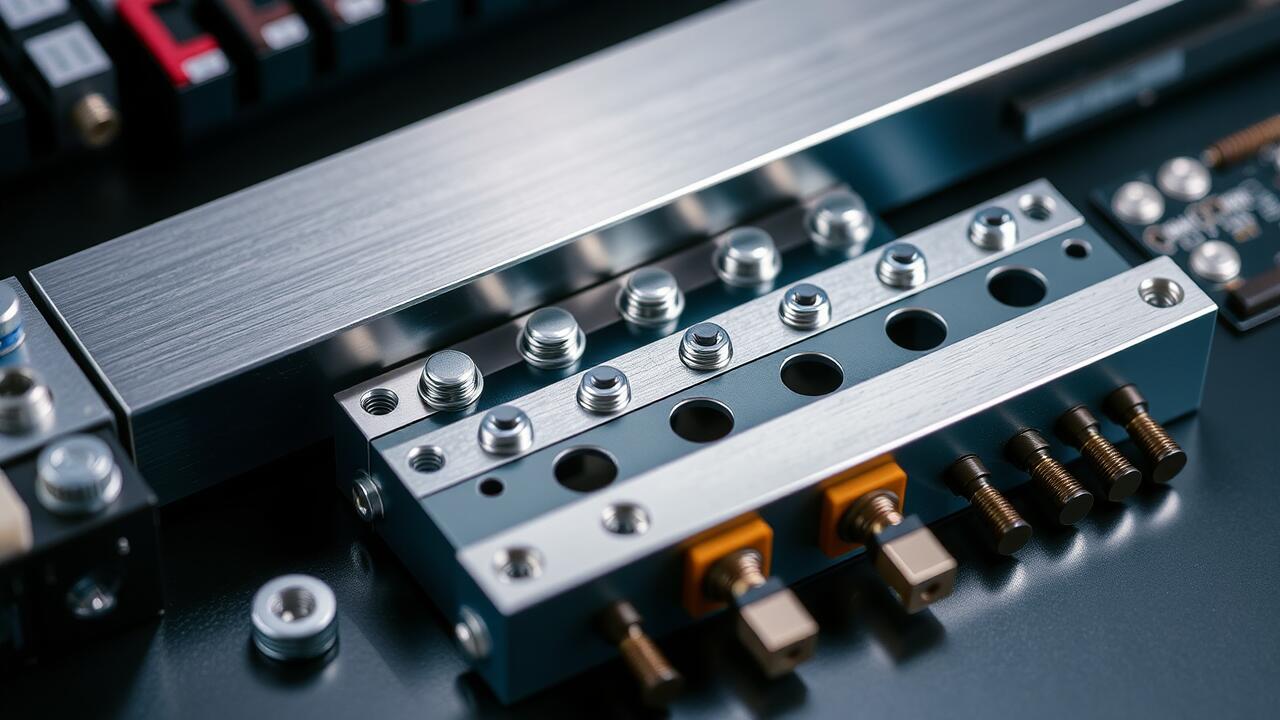

Custom Aluminum Busbars play a vital role in modern electrical systems, serving as crucial components for efficient power distribution. These bus bars, made from aluminum, are designed to carry significant electrical loads while maintaining performance and safety standards. Their lightweight nature and excellent conductivity make custom aluminum busbars an ideal choice for a range of applications. Companies often opt for custom solutions to meet specific requirements, enhancing adaptability and functionality. With various designs available, aluminum bus bars can meet the diverse needs of industrial and commercial sectors, ensuring optimal performance in power distribution systems.

- Custom designs can cater to unique space constraints and electrical load requirements.

- Aluminum busbars provide superior heat dissipation compared to copper alternatives.

- They are resistant to corrosion, which increases their lifespan in challenging environments.

- Customization options include different shapes, sizes, and finishes to fit specific applications.

- Busbars can be integrated with advanced monitoring systems for enhanced reliability.

- They are lightweight, reducing installation costs and facilitating easier handling.

- Custom aluminum busbars contribute to overall energy efficiency in electrical systems.

Definition and Purpose of Busbars

Custom Aluminum Busbars serve as critical components in electrical distribution systems, acting as conductive pathways for electricity. These bus conductors are made from aluminum alloy materials, such as 6061-T6 aluminum, which provide a lightweight yet robust solution for power transmission. According to aluminum.org, the use of aluminum in busways enhances efficiency and reduces energy losses, making it an ideal choice for various applications.

The primary purpose of Custom Aluminum Busbars is to facilitate the distribution of electrical power while ensuring safety and reliability. Their design allows for easy integration into existing systems, minimizing installation time and complexity. Busways equipped with aluminum busbars can handle high currents and voltages, providing effective performance compared to traditional steels. This versatility makes them suitable for many industries, from renewable energy to heavy manufacturing.

Advantages of Custom Aluminum Busbars

Custom Aluminum Busbars offer significant benefits in various applications, particularly within the automotive and transportation sectors. Their lightweight nature makes them ideal for enhancing the efficiency of hybrid vehicles and other automotive designs. Unlike stainless steel and traditional steel busbars, aluminum busbars reduce overall weight without compromising electrical performance, making them a preferred choice in modern vehicle manufacturing.

The versatility of Custom Aluminum Busbars extends to their ability to integrate with different materials such as alloy steels and expanded metal. This adaptability allows for innovative design solutions that cater to specific needs within power distribution systems. Their corrosion resistance and excellent conductivity further enhance their utility, making them essential components in both industrial and commercial applications where reliability is paramount.

Types of Aluminum Busbars

Custom Aluminum Busbars are categorized into various types to meet specific industry requirements. Standard aluminum busbars are engineered for general applications, providing reliable performance in panelboards and electrical distribution systems. Flexible aluminum busbars offer adaptability in complex layouts, ideal for aerospace and other industries with rigorous space constraints. These busbars are often manufactured using advanced milling and machining techniques, ensuring optimal alloy properties that enhance electrical conductivity. Incorporating tin plating in manufacturing enhances corrosion resistance, making these custom solutions suitable for diverse environments. Each type serves a distinct purpose while maintaining the essential benefits of custom aluminum busbars in modern applications.

Standard Aluminum Busbars

Standard aluminum busbars serve as a fundamental component in electrical systems, facilitating efficient power distribution. Their design typically includes a flat or rectangular shape, allowing for easy installation and integration into various setups. These components are often used in conjunction with custom aluminum busbars, providing versatility for both standard and unique applications. Utilizing aluminum bus bars ensures a lightweight solution that does not compromise on performance, making them an ideal choice for modern electrical systems.

The manufacturing process for standard aluminum busbars is streamlined to meet a variety of specifications and packaging requirements. This efficiency in production allows for cost-effective solutions while maintaining high-quality standards. Custom aluminum bus options further enhance their utility by catering to specific project needs, resulting in tailored solutions for industries ranging from renewable energy to heavy manufacturing. The flexibility and performance of aluminum busbars make them a preferred choice for many installations, ensuring reliability in power transfer and distribution.

Flexible Aluminum Bus for Enhanced Adaptability

The adaptability of custom aluminum busbars makes them an attractive choice for various busbar applications. Flexible aluminum bus solutions can conform to unique installation requirements without compromising electrical performance. Options like laminated busbars and aluminum bus pipes enhance flexibility, allowing for intricate setups in compact spaces. These custom busbars also ensure that the integrity of the electrical system remains intact, outperforming solid busbar designs in certain scenarios.

Using flexible aluminum bus provides significant advantages over traditional copper busbars. The lightweight nature of aluminum reduces structural requirements and eases installation efforts. This adaptability is essential for industries that demand customized solutions, where top aluminum bus configurations can mitigate space constraints while delivering excellent conductivity. As a result, custom aluminum busbars serve as a practical solution for dynamic environments requiring both versatility and efficiency.

Aluminum Busbar Capabilities

Custom Aluminum Busbars are designed to meet a wide range of operational requirements, showcasing capabilities that cater to various industries. Stock busbars provide standard solutions, while extra-large busbars and flexible busbars are ideal for specialized applications where adaptability is crucial. The advanced busbar fabrication techniques allow for the creation of both rigid and flexible configurations, ensuring optimal performance in diverse environments. Customized busbar solutions can include unplated busbars for unique electrical properties or tailored aluminum bus conductors for specific conductivity needs. Each type of busbar plays a vital role in enhancing electrical conductivity, ultimately contributing to the efficiency of power distribution systems.

Electrical Conductivity and Performance

Custom Aluminum Busbars are known for their excellent electrical conductivity, making them ideal for various power distribution systems. The use of aluminum bars enhances performance while maintaining lightweight characteristics. A cu-al busbar can outperform copper counterparts in certain applications, resulting in more efficient energy transfer. The design flexibility allows for short busbar configurations that can fit compact spaces, ensuring optimal functionality in tight environments.

The performance of flexible busbar designs further enhances the adaptability of Custom Aluminum Busbars in different sectors. Manufacturers can create braided busbar options for improved current distribution, making them suitable for high-load applications. This customization ensures that the aluminum bar meets specific electrical demands, providing reliability and durability. With the right design and manufacturing techniques, these custom aluminum solutions can outperform standard busbars in efficiency and longevity.

| Busbar Type | Material | Maximum Load (A) | Dimensions (mm) | Application |

|---|---|---|---|---|

| Standard Aluminum Busbar | Aluminum | 1000 | 50 x 10 | Power Distribution |

| Cu-Al Hybrid Busbar | Copper/Aluminum | 1200 | 75 x 15 | High-Load Applications |

| Flexible Braided Busbar | Aluminum | 1500 | 30 x 5 | Compact Spaces |

| Sheet Busbar | Aluminum | 800 | 100 x 5 | Low Voltage Systems |

Customization Options for Specific Applications

Custom Aluminum Busbars can be tailored to meet the specific requirements of various electrical applications. Clients can request bus bars with different dimensions and shapes, allowing them to fabricate bus bars that fit their unique setups. The option to order thicker bus bars enhances load-bearing capacity, ensuring they can handle greater electrical demands. Companies can design their own buss bars to optimize performance and space efficiency, making them ideal for high-performance systems.

Tailoring the bus bar material is crucial for achieving desired conductivity and thermal performance. While copper bus bars are well-known for exceptional conductivity, Custom Aluminum Busbars are often preferred for their lightweight and corrosion-resistant properties. By selecting the right bus bar products, customers can ensure that they meet safety standards and operational efficiency. This customization process allows for an enhanced integration of bus bars into existing systems while maximizing their lifespan and reliability.

Busbar Manufacturing Technology

Manufacturing techniques for Custom Aluminum Busbars have evolved significantly, enabling the production of high-voltage busbars and low voltage busbars tailored for various applications. The versatility of aluminum offers advantages such as lightweight construction and excellent conductivity, making it a preferred choice for electrical bus bars. Advanced bus bar fabrication processes ensure high precision and durability, facilitating custom designs that meet specific performance requirements. Innovations in bus packaging and aluminum connectors enhance the integration of these products into power distribution systems, driving efficiency and reliability in both industrial and commercial environments.

Innovations in Aluminum Busbar Production

Recent advancements in manufacturing technology have significantly improved the production of Custom Aluminum Busbars. High-quality aluminum materials are now utilized to enhance electrical performance and durability. The integration of aluminum air techniques has streamlined the cooling process, ensuring that heat generated during operation is effectively dissipated. Manufacturers are consistently focusing on creating the correct bus bar design that meets specific operational requirements. Innovations in bus bar connectors have also emerged, allowing for more reliable and efficient connections between components.

The shift towards lighter and more flexible designs has led to the utilization of aluminum pipe structures in busbar systems. These designs not only reduce overall weight but also enhance adaptability in various applications. Custom Aluminum Busbars can now be produced with a variety of configurations tailored to meet unique operational demands. The use of aluminum materials ensures cost-effectiveness while maintaining high performance and reliability across different industrial settings. This evolution in manufacturing has established a new standard for efficiency and effectiveness in busbar technology.

| Feature | Description | Benefits |

|---|---|---|

| High-Quality Aluminum | Use of advanced aluminum alloys for busbars | Improved electrical performance and durability |

| Aluminum Air Techniques | Integration of innovative cooling mechanisms | Enhanced heat dissipation during operation |

| Flexible Designs | Implementation of lightweight aluminum pipe structures | Reduced weight and increased adaptability |

| Custom Configurations | Tailored busbar solutions for specific applications | Optimized performance for unique operational demands |

Comparison with Copper Busbars

Custom Aluminum Busbars offer several key advantages over copper busbars. Aluminum conducts electricity well, making it a reliable choice for various bus systems. The lightweight nature of aluminum allows for easier installation and handling, particularly in applications where aluminum angles and aluminum rods are used. Bus bar fasteners designed for aluminum systems enhance the overall efficiency and durability, ensuring a strong connection that maintains high performance over time.

Cost-effectiveness is another significant factor when choosing between aluminum and copper. Custom Aluminum Busbars are generally less expensive to produce, which can be a deciding factor for large-scale projects. The seamless bus pipe design in aluminum busbars minimizes resistance and further enhances electrical performance, distinguishing them from traditional copper busbars. With advancements in manufacturing technology, aluminum busbars continue to evolve, providing reliable options for modern electrical needs.

Applications of Aluminum Busbars

Custom Aluminum Busbars are integral in various applications, particularly in power distribution systems where efficient electrical connectivity is crucial. Their lightweight nature and excellent conductivity make them preferable over traditional materials. Industries such as transportation product manufacturing benefit from the versatility of using aluminum plates, aluminum round rods, and aluminum coils to create optimal configurations. The 6063-T52 aluminum offers a balance of strength and flexibility, making it suitable for assembly with other materials like aluminum sheets. This adaptability extends the use of Custom Aluminum Busbars in conjunction with aircraft alloy steels, enhancing overall performance in contexts like electrical busway systems.

- Enhanced electrical efficiency in power distribution systems

- Lightweight alternative to copper busbars

- Used in transportation product manufacturing for custom configurations

- Adaptable for assembly with various aluminum products

- Suitable for high-performance applications in electrical busway systems

- Corrosion resistance benefits in challenging environments

- Cost-effective solution for large-scale electrical projects

Power Distribution Systems

Custom Aluminum Busbars play a crucial role in power distribution systems across various sectors, including the transportation industry. Utilizing 6063-t52 aluminum alloy, these busbars provide excellent conductivity and corrosion resistance, making them ideal for demanding environments. They are especially beneficial in the transportation industries where reliability and efficiency are paramount. Feeder busways are often integrated with Custom Aluminum Busbars to effectively distribute power to various components, ensuring smooth operation of electrical systems.

The versatility of Custom Aluminum Busbars extends beyond traditional applications. They can be manufactured to fit within metal enclosures and are compatible with auto body panels, providing streamlined solutions for power management in vehicles. The lightweight nature of aluminum combined with the strength of the 6063-t52 alloy makes these busbars an optimal choice for modern power distribution systems. By employing Custom Aluminum Busbars, manufacturers can enhance the overall performance and safety of their electrical setups.

Industrial and Commercial Uses

Custom Aluminum Busbars play a crucial role in various industrial and commercial applications. These busbars are often utilized in power distribution systems, including distribution panels and warehouse facilities. The lightweight yet strong nature of aluminum makes it an ideal choice for manufacturing parts used in equipment that requires efficient power management. Industries such as trailer construction benefit from the versatility of custom bar design, which allows for optimized performance within specific operational contexts.

The adaptability of Custom Aluminum Busbars extends to different configurations suited for various needs. They can be engineered for integration with carts and other transport vehicles, ensuring reliable power distribution without added weight. Their design versatility enables them to serve in both large-scale industrial setups and smaller commercial environments. This flexibility in design and application underscores the importance of Custom Aluminum Busbars in modern infrastructure.

Selecting the Right Busbar Products

Choosing the right busbar products requires careful consideration of various factors to ensure optimal performance for specific applications. Custom Aluminum Busbars are ideal for heavy-duty applications due to their lightweight yet robust nature. Evaluating parts such as bar thickness is essential, as it directly impacts the busbar’s current-carrying capacity. Engaging a custom manufacturer can provide tailored solutions that meet unique specifications, ensuring the busbars can effectively accommodate electrical loads. Innovations in manufacturing processes also play a role in determining the quality and durability of these components, as well as their compatibility with other materials like stainless steel and aluminum tubes.

Conclusion

Custom Aluminum Busbars serve as a pivotal solution in various electrical distribution systems, offering a lightweight alternative to traditional copper busbars. With their impressive electrical conductivity and performance, these custom busbars have found a wide array of busbar applications in both industrial and commercial environments. The versatility of aluminum bus, whether in the form of solid busbar or laminated busbars, enhances adaptability to specific requirements. Innovations in aluminum bus pipe manufacturing technology continue to strengthen the reliability and efficiency of these products. By selecting top aluminum bus options tailored to unique needs, businesses can ensure optimal power distribution and operational efficiency.

FAQS

What are the benefits of using aluminum bus bars in manufacturing and how do they compare to other materials?

Aluminum bus bars, or aluminum bus bar systems, are widely recognized for their lightweight and high conductivity properties. They offer a reliable aluminum metal solution for various electrical applications. Compared to copper, aluminum busbars are more cost-effective and provide excellent performance in a warehouse facility setting. When choosing to manufacture bus bars, aluminum is often preferred due to its corrosion resistance and ease of installation.

How do custom aluminum busbars differ from rigid busbars made of other materials in terms of performance and applications?

Custom aluminum busbars are specifically designed for optimal performance in various applications, showcasing all the advantages of aluminum can, such as lightweight and high conductivity. In contrast, rigid busbars made of other materials may not offer the same level of flexibility and efficiency as aluminium busbars. The unique properties of aluminium, combined with custom designs, allow for better heat dissipation and lower resistance, making them a preferred choice in many electrical systems.

How can custom aluminum busbars be tailored for specific applications in electrical systems?

Custom aluminum busbars can be designed with particular dimensions, shapes, and configurations to meet the unique needs of various electrical systems. By adjusting factors such as size and conductivity, they can optimize performance and efficiency for specific applications, providing versatility compared to standard busbars.

What are the common applications for custom aluminum busbars in various industries?

Custom aluminum busbars are commonly used in several industries, including renewable energy systems such as solar panels, electrical distribution networks, industrial automation equipment, and transportation systems. Their lightweight nature and excellent conductivity make them ideal for applications requiring efficient electrical connections.

What should you consider when selecting custom aluminum busbars for your electrical project?

When selecting custom aluminum busbars for your electrical project, you should consider factors such as the specific electrical requirements, the environment in which they will be used, and compatibility with existing systems. It’s important to evaluate their conductivity, mechanical strength, and dimensional tolerances to ensure optimal performance and reliability in your application.

Comments are closed.